Get to know an ExMesh™ fence…

Our ExMesh™ security fences are highly durable and are easy to install… and they are used to protect people, property and infrastructure.

Not familiar with an ExMesh™ fence and how it differs from a palisade fence?

We’ve put together a handy guide to help you!

Firstly, let’s look at the mesh itself…

How is mesh fencing made?

Expanded metal is manufactured using a ‘slit and stretch’ method – metal sheets are fed into our expansion machines and the result is a diamond shaped pattern with angular strands which are inclined from the plane of the expanded metal sheet.

In this form, the expanded metal is known as ‘raised mesh’ and this is the material used in our fences.

The homogenous design of expanded metal results in an inherently strong material: it’s therefore very robust – and perfect for use in fencing!

In addition, as the fencing is made from one piece of material there is nothing to work loose, no fretting strands or strained joins or welds. This means that it does not suffer from the same security vulnerabilities as palisade, wire mesh, welded mesh, chain-link or woven wire fencing.

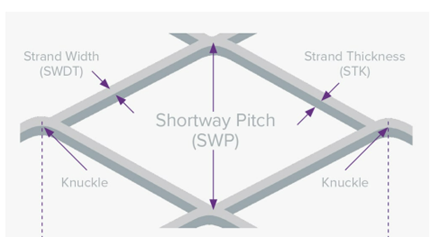

How is raised mesh measured?

The key measurements for the raised mesh used in our fencing are Longway Pitch (LWP), Shortway Pitch (SWP), Strand Width (SWDT) and Strand Thickness (STK).

LWP, measured horizontally from either knuckle to knuckle or centre to centre, is derived from the size of tooling used within the production process.

SWP, measured vertically from either knuckle to knuckle or centre to centre, is manifested through the overall expansion applied during manufacture.

SWDT is a measurement of the width of the resulting angular strand created during manufacture.

STK is a measurement of starting raw material thickness. Contrary to belief, the expanding process does not directly alter material thickness. Strand thickness should not be confused with the overall height or depth of expanded metal. Typically, mesh height can be as much as 1-2x the measurement of SWDT.

What else do you need to know about mesh fencing?

Open area. This is the percentage of the open ‘diamonds’ in an expanded metal sheet, in relation to the amount of the sheet taken up by the metal strands themselves. If a mesh pattern has a high open area, it means that the diamond shapes are large and vice versa. The open area of fencing is typically a balance between security and visibility.

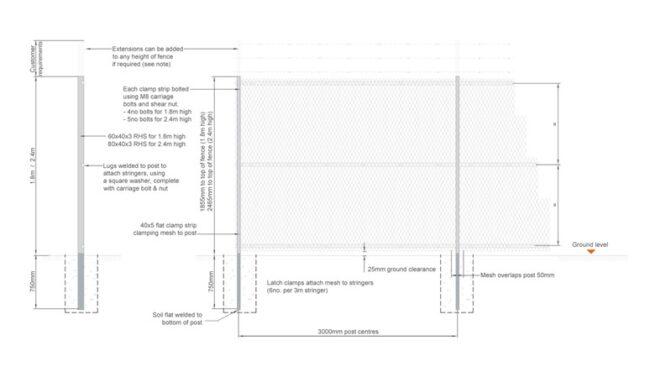

Panel sizes. These are normally presented as H x W. Typical panel sizes for our ExMesh™ Fastrack fencing are 1830 x 3000mm and 2440 x 3000mm. However, other sizes are available.

Ground clearance. This refers to the distance between ground level and the bottom of the fence panel. Typically, this is very small for security purposes. In the case of ExMesh™ Fastrack it is 25mm.

However, the fence panel can be buried into the ground for an increased level of security.

Overlapping. This is the distance a mesh panel overlaps the fencing post – in the case of ExMesh™ Fastrack it is 50mm to 80mm.

Coatings. This is the coating that is used to protect the fencing panel from corrosion – and it can also add an aesthetic element to the panel. As a minimum, all ExMesh™ fencing panels are hot dip galvanised to protect the steel from corrosion.

Polyester powder coating can be used to add colour and more aesthetic appeal to the fence, should it be needed.

Post type. Typically, a fencing post will be a Rectangular Hollow Section (RHS) steel fence post – an alternative would be the Square Hollow Section (SHS) post. ExMesh™ uses S235/S275JR steel, which is the structural standard.

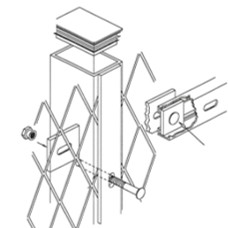

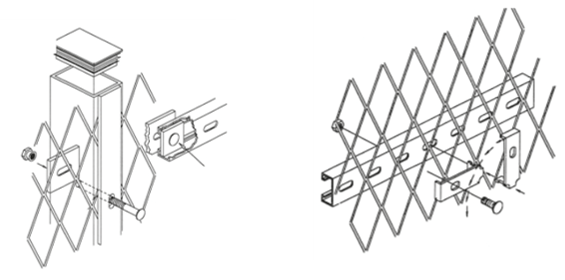

Stringers. Security fence stringers are the horizontal ‘rails’ which fit on to the face of the welded ‘post lugs’ so that when the mesh is ready to be put in place, it fits flush along the face of the post. There are typically three stringers per bay and they are attached by latch clamps, bolts and nuts.

Post fixings. This is the method of fixing the fencing panel to the post during installation. A combination of carriage bolts and shear nuts is typically used in the installation of an ExMesh™ fence.

Latch clamps. Latch clamps are the fixings which are used to attach the metal mesh fencing panels to the stringers.

Clamp strip. Clamp strips are used in the installation process and are bolted to the posts using the fixing methods referred to above.

Post centre. The post centre is the centre of the fencing post – distance between posts should be measured from post centre to post centre. For fencing systems that are 1.8m high, the post centre to post centre distance is 3000mm. For fencing systems that are 3m high, the distance should be 2400mm.

Post depth. This is the depth a fence post should be buried to ensure stability – in the example of ExMesh™ Fastrack, it is 750mm.

Below is an example of our ExMesh™ Fastrack security fence, which will help you understand more about its construction.

Get to Know our Core Mesh

- 2089 – large, raised, steel mesh. A robust mesh solution, you will find this mesh in our security fencing panels and cages, including our ProtEx 1 LPS 1175 A1 (SR1) accredited system.

- 4095 – large, raised, steel mesh. A durable mesh, it is often used within our security fencing panels. In comparison to our 2089 mesh panel this mesh has a larger open area.

- 4097 – large, raised, steel mesh. A durable mesh, it is mainly used in our Telecoms system and is a slightly lighter gauge mesh than our 4095.

- 1576 – large, raised, steel mesh. Found in our high security fencing range this mesh benefits all of our regular features and is specifically used in our LPS 1175 B3 and C5 accredited systems.

- 7732 – large, raised, steel mesh. This is the original parallel strand high security mesh. It has an exclusive profile mesh pattern to deter cutting and climbing.

If you’d like to know more about ExMesh™ fencing and would like to access our expertise in security fencing manufacture and installation, contact the team here.